-

Base oil definition

Viscosity between 10 and 50 obtained by further refining the remaining oil when distilling crude oil at atmospheric pressure It has the function of a lubricant that reduces friction as oil.

Base oil is the main raw material of all petroleum lubricant products. Like base oil products such as gasoline, kerosene and diesel, Since it is derived from crude oil, it is called "mineral oil-based lubricant". Separately from Base oils obtained through chemical synthesis using the above chemicals as starting materials are called

“chemical synthetic oil-based lubricants”.

Complex composition, varying viscosity and ingredient content depending on the manufacturing process, high percentage of finished lubricant The qualityBase oil classification

1. American Petroleum Institute Classification-1994

American Petroleum Institute Classification-1994 Classification Saturated

hydrocarbonsulfur Viscosity index Group Ⅰ < 90% and / or < 0.03% and 80 ≤ Ⅵ 120 Group Ⅱ ≥ 90% and ≥ 0.03% and 80 ≤ Ⅵ 120 Group Ⅲ ≥ 90% and ≥ 0.03% and Ⅵ ≥ 120 Group Ⅳ PAO(Poly Alpha Olefin) Group Ⅴ Ester & Others The base oils produced by solvent extraction in general mineral oil bases are mainly in Group I, and the base oils produced by hydroforming reforming are in Group II.

VHVI base oils manufactured by highly hydrocracking reactions such as YUBASE are mainly group III.

Group IV base oils are PAO (Poly Alpha Olefins) and are synthetic lubricating base oils.

Group V base oils are other base oils such as esters and glycols, which are synthetic base oils.2. Classification by composition

Classification by composition Paraffin, % Naphthen, % Aromatics, % Paraffin Base Oil 45~60 20~30 15~25 Napsen base oil 15~25 65~75 ~10 Aromatic base oil ~5 60~75 20~25 Basically, the composition of mineral oil is greatly influenced by the crude oil used for the first time.

In recent years, however, it is not simply purified by fractionation or extraction.

Since base oils are often manufactured by reactions such as conversion, the composition of the final base oil product is very different from that of the original crude oil because it is less influenced by crude oil.3. Base oil classification according to viscosity index

Base oil classification according to viscosity index Range Classification Ⅵ 40 Low Viscosity Index(LVI) 40 ≤ Ⅵ 80 Medium Viscosity Index(MVI) 80 ≤ Ⅵ 120 High Viscosity Index(HVI) 120 ≤ Ⅵ 140 Very High Viscosity Index(VHVI) 140 ≤ Ⅵ Ulta High Viscosity Index(UHVI) Viscosity index refers to the degree of change in viscosity with temperature. The higher the viscosity index, the smaller the change in viscosity with temperature.

Viscosity index is representative of the quality of base oil. In the case of YUBASE, the viscosity index is over 120 and is divided into VHVI.4. Base oil classification by viscosity

Neutral Number

Neutral base oil refers to the distillation from the tower during distillation under reduced pressure, and the acidic base oil fraction (atmospheric residue) changed to neutral after purification. Uses the expression Neutral in its meaning.

Base oil classification by viscosity Neutral 40℃ 100℃ cSt SUS cSt SUS 70N 13.3 70.8 3.0 37.0 100N 21.5 104.0 4.0 39.0 150N 31.6 148.0 4.9 42.4 250N 56.1 257.0 6.5 47.0 500N 107.0 496.0 11.0 64.0 600N 130.4 604.0 12.1 66.0 BRIGHT STOCK

Bright stock is used in the sense that very turbid and black is turned into bright oil. Generally, solvent is used to distill the residue under reduced pressure. Manufactured by De-waxing and Hydro-treating.

Base oil classification by viscosity Bright Stock 40℃ 100℃ cSt SUS cSt SUS 135BS 413.2 1875 28.6 135.0 150BS 568.0 2632 33.0 155.0 175BS 654.7 3034 36.0 169.7 PRODUCT NAME

In general, the kinematic viscosity (cSt) value of 100 ° C is added, and in case of YUBASE 4, 100 ° C kinematic viscosity is 4 cSt, and in the case of YUBASE 6, 100 ° C kinematic viscosity is 6 cSt.

-

Manufacture of base oils

1.Purpose of refining

Lubricant base oils contain a variety of chemicals, including the following, which are not useful for lube base oils.

Chemical species useful as lube base oil

Chemical species useful as lube base oil Chemical type Reason Iso Paraffin High viscosity index Sulfur compounds (thiophenes) Sulfur compounds (thiophenes) Chemical species that are not useful as lubricant base oils

Chemical species that are not useful as lubricant base oils Chemical type Reason Long Chain Paraffin (Wax Type) High pour point adversely affects low

temperature performanceAromatic compounds Sludge generation, carcinogenic Unsaturated compounds Sludge / varnish generation Chlorine / Nitrogen Compounds Promote oxidation In order to obtain high quality base oil, the process of purification, such as removal, maintenance and conversion of the above species, removes the substances that hinder performance and obtains useful substances.

2. Manufacture process

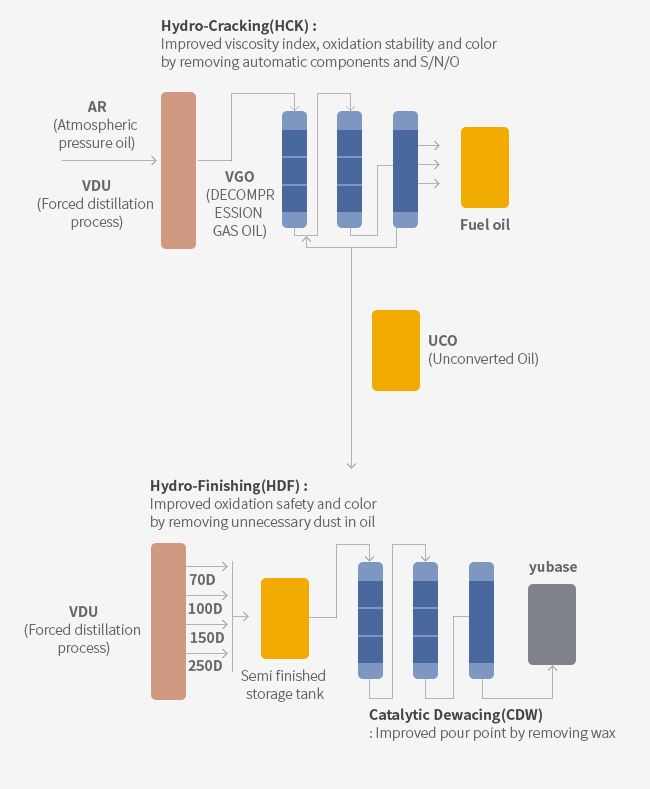

Lubricant base oils can be obtained through a variety of processes, which are different in their quality and properties.

The basic unit process and function are as follows. In addition, the process flow diagram of YUBASE manufacturing is shown below.Lubrication Base Oil Manufacturing Unit Process

Lubrication Base Oil Manufacturing Unit Process Classification Function Kinds Vacuum

Distillation· Separation of atmospheric residual oil by desired viscosity

· Viscosity and volatilization performance of base oils are determinedDearomatic

Process· Aromatic component and S / N / O removal

· Ⅵ, Oxidation Stability, Color ImprovementSolvent Extraction

Hydro-Treating

Hydro-CrackingDewaxing

Process· Improved Pour Point by removing Wax (Low temperature performance)

· Ⅵ decreases slightlySolvent Dewaxing

Catalytic DewaxingHydrofinishing

Process· Hydrotreating unsaturated hydrocarbons

· S / N / O Compound Removal

· Increases thermal and oxidative stability and brightens colorsClay

Hydro-finishingYUBASE Manufacture process

Vacuum Distillation Unit, VDU

Lubricant base oil is a mixture of complex hydrocarbons, and usually has a boiling point above 350 ° C at atmospheric pressure, so the oil cannot be obtained from the CDU separating ordinary petroleum products. Therefore, distillation of crude oil from crude oil under reduced pressure distillation through the so-called 'decompression distillation tower' enables the separation of the basic oil base oil.

Dearomatic Unit

The fractions classified in the VDU contain a large amount of Aromatic fractions that impair the viscosity index and oxidative stability and thus undergo a Dearomatic process to remove them.

-

Hydro-Treating

Hydrogenation in a catalyst-packed reaction tower converts aromatic compounds to saturated hydrocarbons, some of which are also paraffinic compounds. Our HBO (SK500N, SK120BS) uses this process.

-

Hydro-Cracking

It is similar to hydrotreating, but the operating conditions are more severe, leading to decomposition reactions than conversion reactions, resulting in a higher rate of conversion of aromatic compounds to naphthenic compounds and naphthenic compounds to paraffin compounds than hydrotreating. The low Aromatic content and the higher paraffin content provide a base oil with high viscosity index and excellent oxidation stability. YUBASE uses this process.

Dewaxing Unit

Wax, a high-level paraffinic hydrocarbon, reduces the fluidity of the oil at low temperatures and easily coagulates. Dewaxing process is used to remove these wax components.

-

Catalytic Dewaxing Unit

In the reaction column filled with metal catalyst, hydrogenation reaction is used to convert to Iso-Paraffin with excellent fluidity.

Hydro-Finishing Unit

In this process, hydrogen is added in the presence of a catalyst to remove unnecessary substances in the oil, which increases the heat and oxidation stability of the oil and changes the color brightly.

-

-

Base oil quality factor

Base oils are complex mixtures of different hydrocarbons and the quality of base oils is governed by many factors.

Representative quality factors are as follows.BASE OIL QUALITY

-

VOLATILITY

Volatile volatility

-

STABILITY

toxicity / flash point

-

CORRESPONDENCE

Aniline

Anti-emulsification -

OCEAN

color / transparency

-

OXIDATION SAFETY

Hydrocarbon Saturation

Aromatic content

S / N Compound Content -

consistency

-

Viscosity / Low Performance

Viscosity vs. Temperature (viscosity index) Low temperature viscosity / Pour point Cloud point

1. Viscosity and Low Temperature Performance

The physical properties that represent the viscosity characteristics of base oils are the viscosity index, and the viscosity index is the stability against the change in viscosity of the oil with temperature changes. In general, oils with a high viscosity index have good low temperature viscosity properties (Cold Cranking Simulator, Brookfield viscosity). Low temperature fluidity means resistance to oil flow at low temperatures.

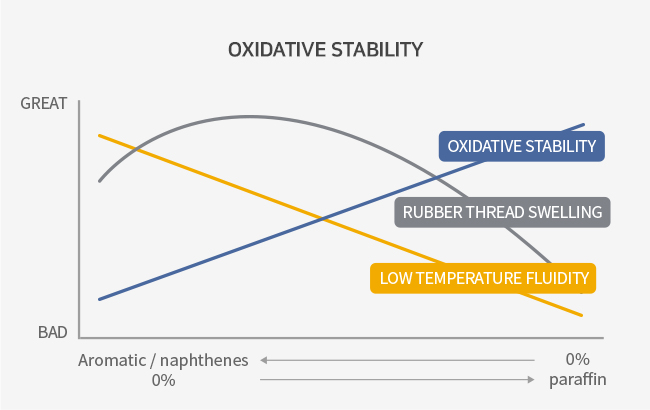

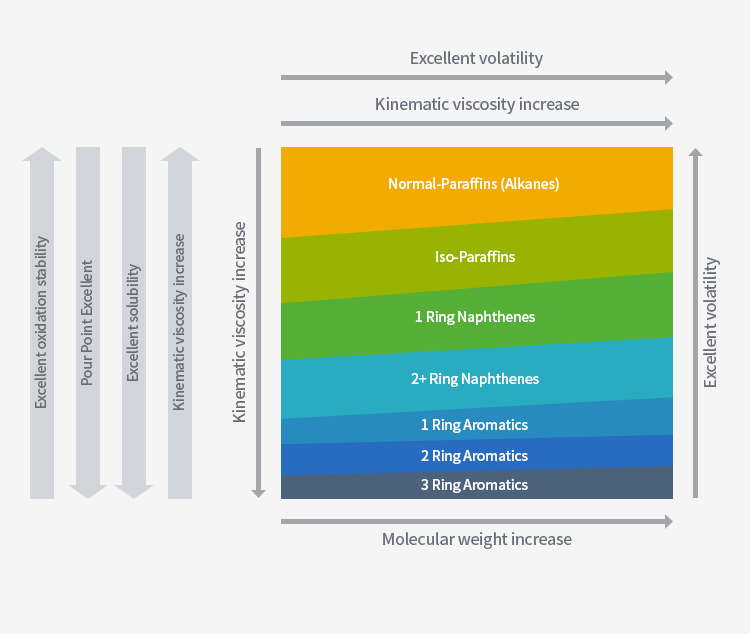

In general, the higher the content of linear paraffins, the higher the viscosity index, but the higher the pour point. Viscosity index / fluid point characteristics according to hydrocarbon type are as follows.Viscosity and Low Temperature Performance Viscosity index Pour point Normal-Paraffins Very High High Iso-Paraffins High Medium Naphthenes Medium Low Alkyl Benzene Depending on the length of the alkyl group Multi-Ring Aromatics Low Low 2. Oxidative stability

Oxidation proceeds with oxygen in the air, which is directly related to the life / performance of the oil. Compared to the oxidative stability of aromatic and naphthenes oils, paraffinic oils have superior oxidation stability.

Oxidative stability Viscosity index Pour point Normal-Paraffins Very High High Iso-Paraffins High Medium Naphthenes Medium Low Alkyl Benzene Depending on the length of the alkyl group Multi-Ring Aromatics Low Low

3. volatility

Volatility refers to the loss of oil in use. The volatility of a base oil is closely related to the molecular weight distribution or the distillation phase of the base oil. In general, oil in the range of 343-399 ℃ of the distillation point distribution determines the volatility of the base oil.

Volatility is also related to the hydrocarbon distribution, which is closely related to the oxidative stability of the oil. In general, volatility tends to increase as the hydrocarbon type is paraffin, naphthenic, and aromatic.

So far, we have looked at the types of hydrocarbons that affect base oil quality factors, their meaning and quality. This is summarized below.

volatility YUBASE

High grade base oilSolvent Extraction Hydro-Treating Severe Hydro-Cracking PAO Viscosity-Temperature Characteristics Fair Good Excellent Excellent Oxidation stability Fair Good Very Good Very Good Low volatility (low viscosity oil) Poor Good Very Good Very Good Low temperature fluidity Poor Good Very Good Excellent Additive compatibility Excellent Very Good Very Good Fair

Base Oil Quality Effect by Hydrocarbon Type

-