Outstanding in all circumstances

Maximized Engine

Performance

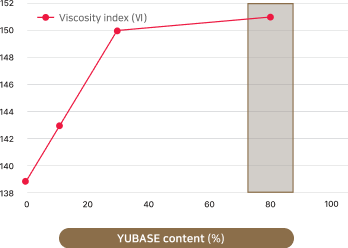

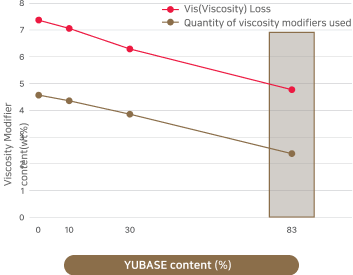

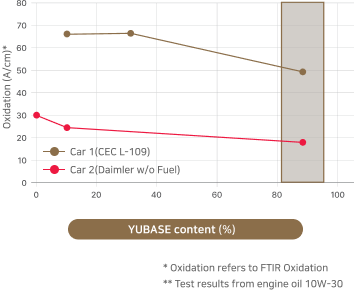

What's special about ZIC's solution is that it maintains the advantage of minimizing viscosity changes while maximizing the advantages of low-visosity engine oil, which helps engines start even at low temperatures and improves fuel efficiency.

ZIC's engine oil is formulated with VHVI Tech, a proprietary technology from SK enmove. This pioneering engineering technology reduces internal friction during engine operation and controls sensitivity to external temperature changes, maximizing both engine efficiency and stability.

for diesel and gasoline

as well as hybrid vehicles

Fuel Efficiency Solution to minimize energy loss

Of the approximate 30,000 parts that form an automobile, 20% generate frictional resistance when the engine is in operation.

ZIC's engine oil, finely blended with YUBASE at an optimal ratio, minimizes frictional resistance and effectively solves causes of low fuel efficiency such as energy loss and engine overload.

for optimal driving experience

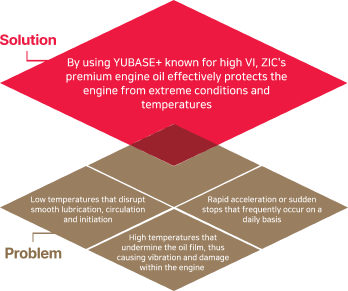

: from drastic temperature changes to severe environments

Engine Protection

Solution

Even low-viscosity engine oil with low friction to increase fuel efficiency has its limitations. Because viscosity varies depending on temperature changes inside and outside the engine and on driving environment.

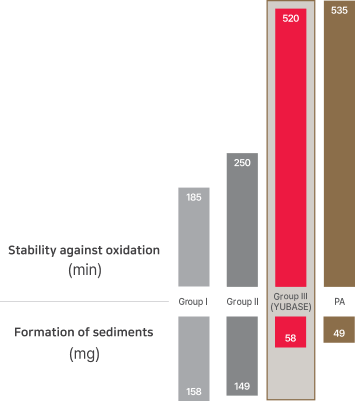

ZIC's solutions, which contain a high content of YUBASE known for its outstanding ability to maintain viscosity stability even during temperature fluctuations, not only keep the engine well lubricated and protected but also help extend the engine's lifespan and minimize sludge and sediments.